Laser vision inspection equipment is a kind of equipment that uses laser technology combined with image processing for high-precision inspection and measurement in industrial production. Includes laser projectors, cameras and image processing software to enable 3D scanning and analysis of product surfaces.

Device function

Distance measurement: The use of laser vision detection technology can accurately measure the distance between the target object and the detection equipment, providing high-precision distance information.

Three-dimensional imaging: Laser vision detection can achieve three-dimensional imaging of the target object, providing more comprehensive spatial information.

Surface shape analysis: Through laser vision detection technology, the surface shape of the target object can be analyzed to detect concavity, flatness and other features.

Contour detection: Laser vision detection can be used to detect the contour of the target object to achieve accurate contour extraction and edge detection.

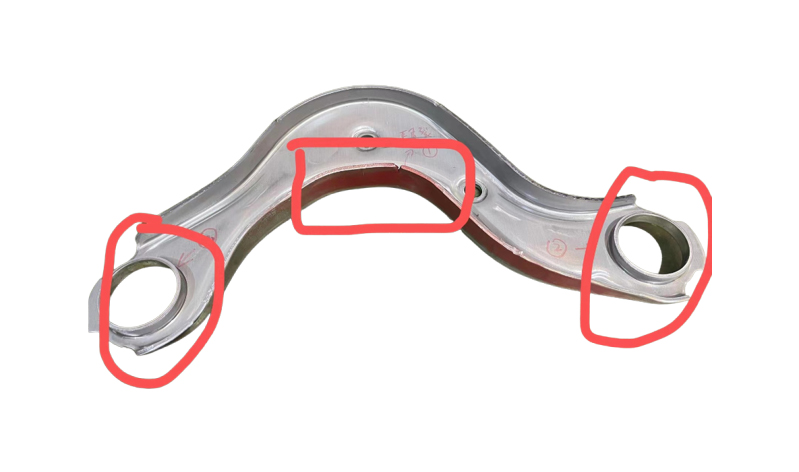

Defect detection: Laser vision detection can detect defects on the surface of the target object, such as cracks, defects, etc., to improve production quality and efficiency.

Measurement of Angle and position: Laser vision inspection equipment can measure the Angle and position of the target object to achieve accurate positioning and fixed Angle.

Speed measurement: Through laser vision detection technology, the speed of the target object can be measured for motion control and monitoring.

Spectral analysis: Laser vision inspection equipment can perform spectral analysis to detect the material and composition of the target object.

Real-time feedback and control: Provide real-time feedback of test results, and integrate with the control system to achieve real-time control and adjustment.

Automatic decision: Based on laser vision inspection results, automatic decision, such as quality determination, product classification, etc.

Equipment advantage

High precision: High precision positioning and measurement capabilities to detect small defects, dimensional changes and other subtle issues.

High-speed inspection: To achieve fast scanning and inspection, applied to high-speed production line real-time inspection needs.

Non-contact detection: Non-contact detection to avoid damage to the product surface, suitable for applications sensitive to the product surface.

Versatility: Laser vision inspection equipment can achieve a variety of functions, such as measuring size, detecting defects, positioning recognition, etc., with strong applicability.

Efficiency: Combined with computer vision technology, laser vision inspection equipment can operate automatically to achieve fast and efficient inspection and analysis.

Strong adaptability: Laser vision inspection equipment can be applied to products of different shapes, materials and colors, and has good versatility.

Flexibility: Can be customized and adjusted according to needs, suitable for a variety of inspection tasks in different industries.

Data processing: Laser vision inspection equipment can perform large-scale data processing and analysis, generating detailed reports and statistics to help optimize production processes.

Reliability: Laser technology is stable and reliable, can maintain high quality detection performance for a long time, and reduce the system failure rate.

Working principle

Laser projection: Laser is used to irradiate on the detected object to form a regular spot or line.

Image acquisition: The camera captures information about the surface of the illuminated object, including the pattern or outline projected by the laser.

Image processing: The captured images are analyzed by image processing software to identify surface shapes, textures, defects and other features.

Measurement and detection: The use of laser vision inspection equipment to measure the size, shape, surface flatness and other parameters of the object, and defect detection.

Product parameter

Device type | Laser vision inspection equipment |

Scope of application | It is suitable for the detection of rubber parts, precision hardware parts, automobile, mobile phone parts, plastic parts, electronic parts and other high-precision products. |

Optical system | Germany high rate CCD industrial camera, Japan imported lens, professional light source system |

Number of cameras | Standard 1 (can be configured according to demand) |

Control system | Germany Siemens Industrial Computer |

Image detection software | Siptech Vision inspection System |

Feed system | Conveyor belt |

Detection speed | 60 ~ 300 PCS/min (depending on product size) |

Recommended inspection size | 30 ~ 200mm |

Detection quality | 5 ~ 500g |

precision | Up to ±0.01mm |

Detection index | Detection of missing, misloading, mixing, defect detection, size detection, screen printing detection, etc |

Supply voltage | Two-phase 220V, 50Hz |

Rated power | 1kW |

Atmospheric pressure | The air pressure is not less than 0.35 ~ 0.7MPa |

Equipment weight | Approx. 150kg |

Operating temperature | -3 ° C to 45 ° C |

Storage temperature | -20℃ ~ 60℃ |

Equipment size | 1900mm(L)×500mm(W)×1300mm(H) |

Application

3D measurement: Suitable for applications requiring accurate 3D measurement, such as automotive parts, electronic products, etc.

Surface inspection: It can be used to detect the flatness, bump, scratch and so on.

Defect detection: used to detect defects, cracks, foreign bodies on the surface of the product.

Positioning and navigation: Used for positioning, navigation and alignment in automated production.

Laser vision inspection equipment provides high-precision and high-efficiency inspection capabilities, and is widely used in manufacturing, electronics industry, medical equipment and other fields, helping to improve product quality and production efficiency.