Visual inspection solution for gear appearance

A visual detector is a device used to automatically detect product appearance defects and dimensional problems, usually used on the production line. It uses cameras and image processing algorithms to detect and analyze the appearance of products and judge whether products are qualified according to pre-set criteria.

Visual detector function

Defect detection

The visual detector can detect the defects on the surface of the product, such as cracks, scratches, stains, oxidation, etc., to ensure the appearance of the product is complete and good quality.

Dimensional measurement

The visual detector can measure the size, length, width, thickness and other parameters of the product to ensure that the product meets the design specifications.

Location recognition

The visual detector identifies the position and orientation of the product to ensure proper handling and assembly.

Character recognition

The visual detector can identify the text, logo or bar code on the product to verify the correctness of the product identification.

Color detection

The visual detector can detect the color of the product to ensure that the product meets the design requirements or specific standards.

Defect classification

Visual detectors can classify products according to detected defects, helping production personnel quickly deal with nonconforming products.

Automatic discrimination

The visual detector can automatically judge the conformity of the product according to the preset standard, and carry out the corresponding treatment.

Data recording and analysis

Visual detectors can record test results and data to help production managers analyze problems in the production process and make improvements.

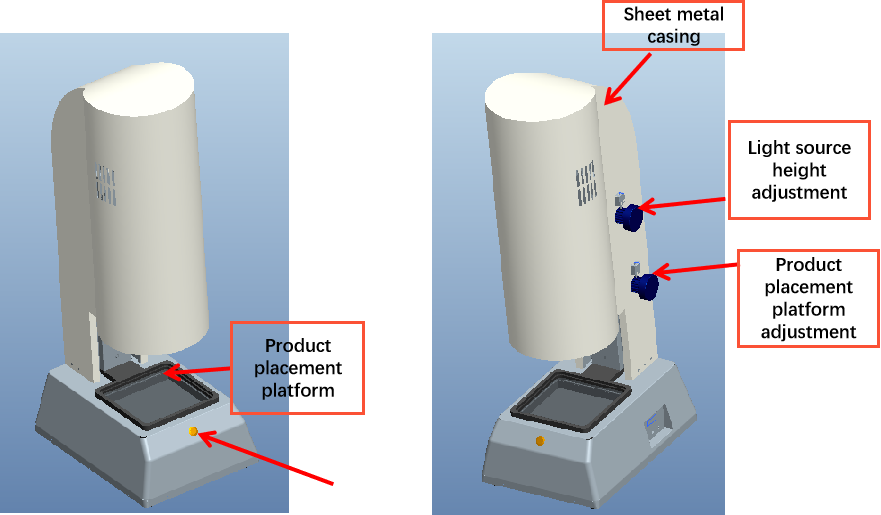

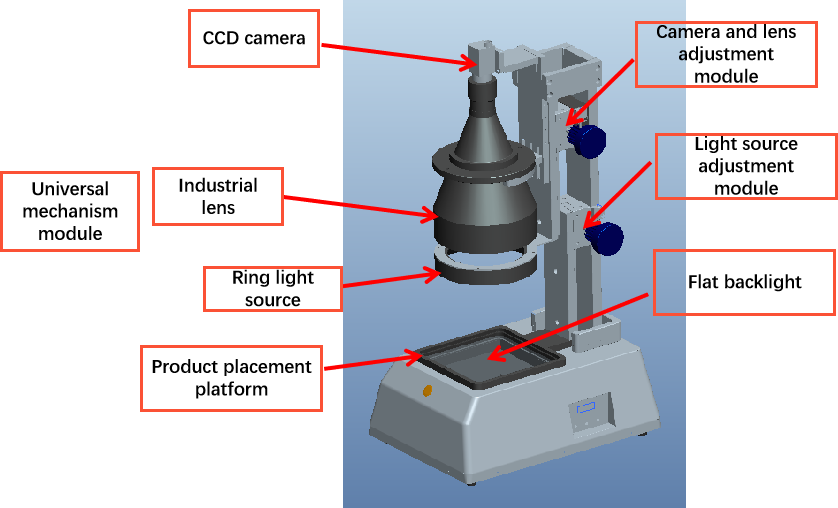

Equipment composition

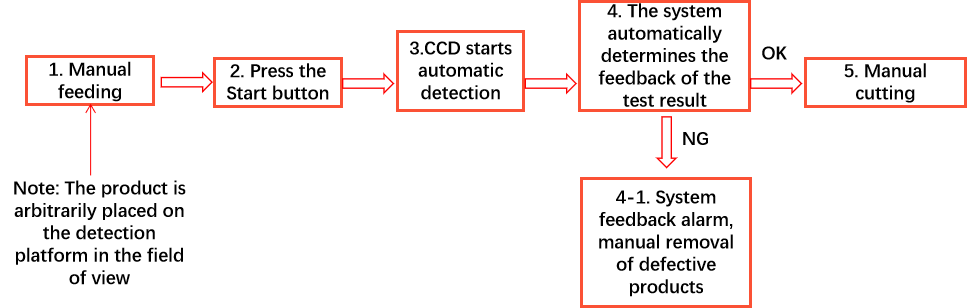

Working principle

Detected object

A gear is a mechanical component used to transmit power and motion, usually made of metal material, with a gear profile structure. Gears are usually used in pairs, transmitting torque and movement through engagement and rotation between gears.

Gear in the manufacturing process of the product tooth damage, manual detection can not guarantee the accuracy and stability. In response to the customer's problem, we use the positive light detection mode of the one-key measuring instrument to ensure that the number of detection-per minute is not less than 100 pieces (depending on the product feeding speed).

Detection effect

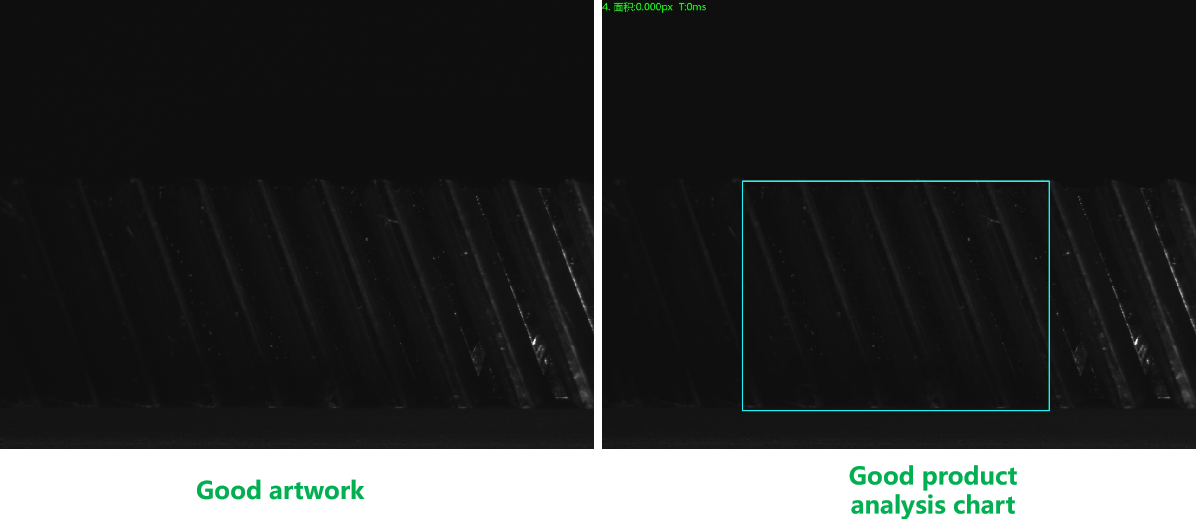

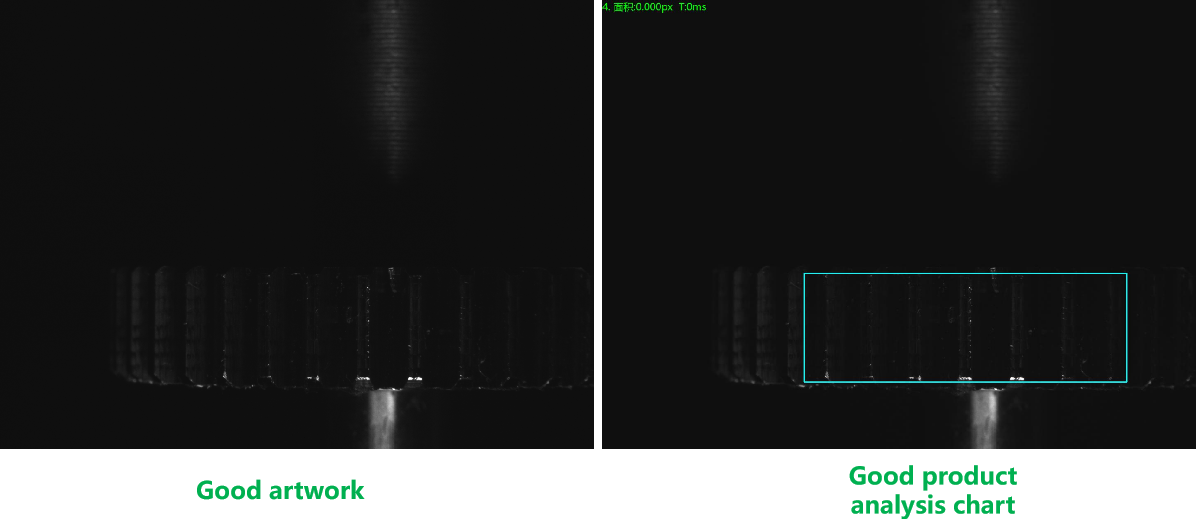

Top positive light detection good product analysis diagram: OK

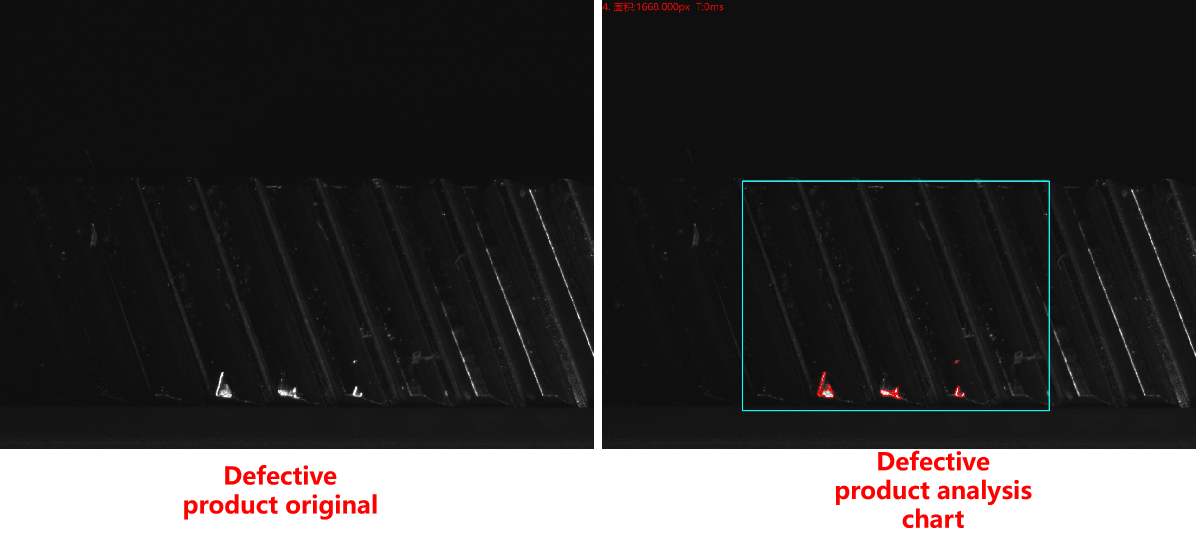

Top positive light detection of defective products analysis diagram: NG Bad feature: knock

Top positive light detection good product analysis diagram: OK

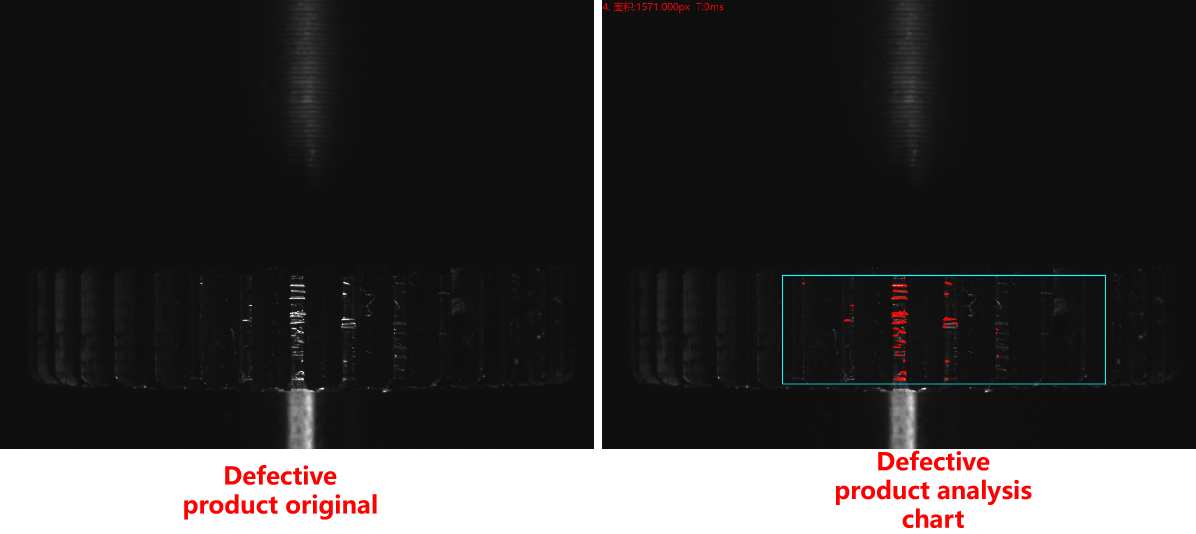

Top positive light detection of defective products analysis diagram: NG Bad feature: knock

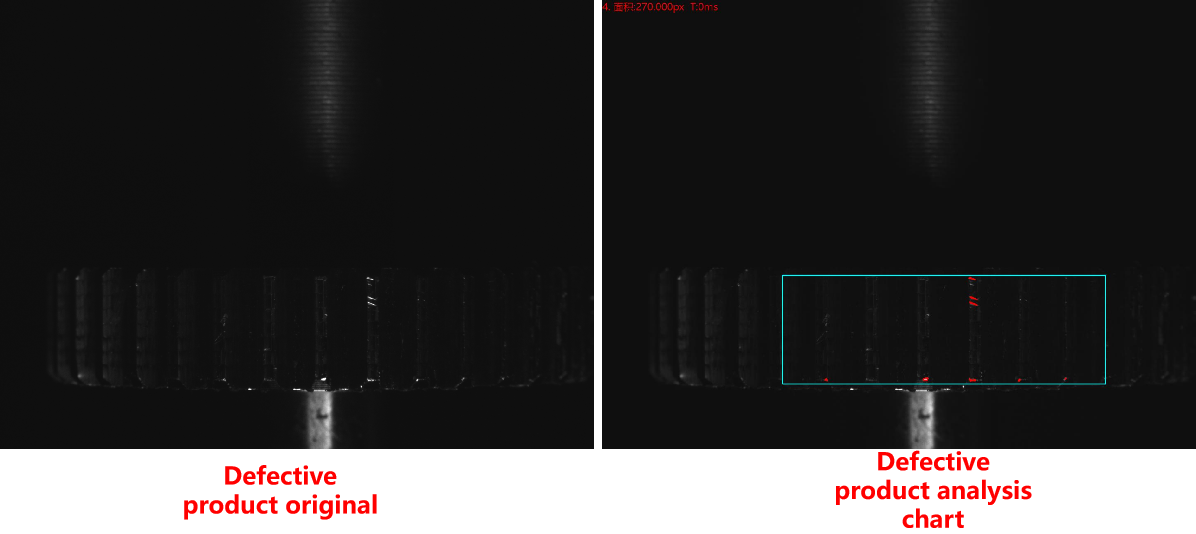

Top positive light detection of defective products analysis diagram: NG Bad feature: knock

-

Service hotline

13077808017