Sealing rubber ring appearance defect visual inspection system

A sealing rubber ring is a round rubber product used to fill, seal or support, usually used to connect two or more parts to prevent leakage or infiltration of liquids, gases or impurities. Provides sealing properties to prevent liquid or gas leaks and reduces vibration, noise and mechanical shock. The sealing rubber ring can also withstand pressure, temperature changes and chemical corrosion. Widely used in automobile, mechanical equipment, pipeline system, hydraulic system, aerospace and other fields.

【 Defect detection 】

Appearance inspection: there are no defects such as damage, cracks, bubbles, deformation or foreign bodies.

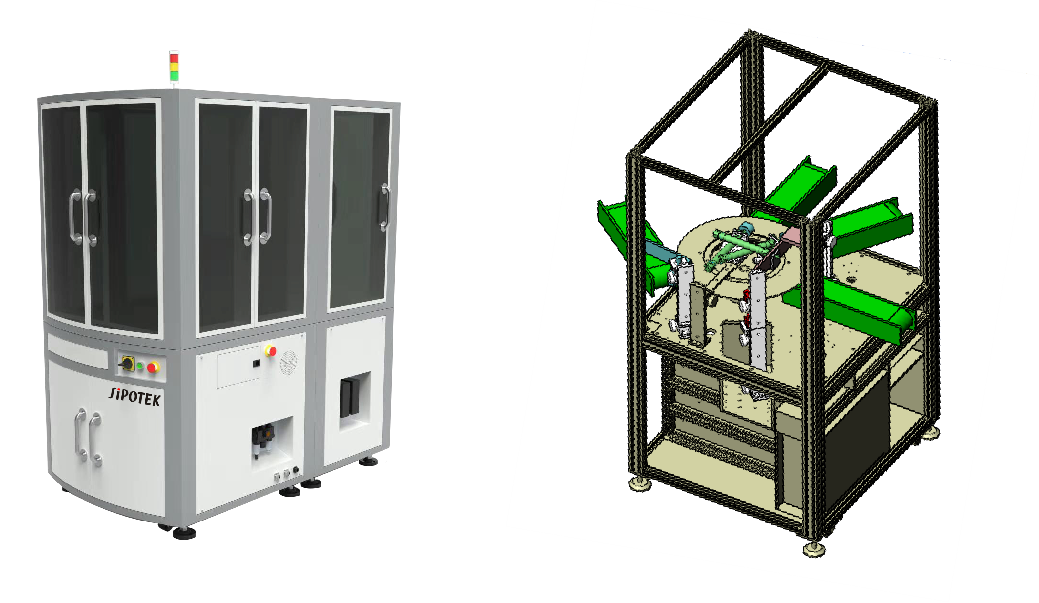

【 Testing equipment 】

【 Technical parameters 】

Detection accuracy: up to ±0.01mm

Detection speed: 200 ~ 1200 PCS/min

Detection accuracy: 99.9%

【 Detection principle 】

Sealing rubber ring visual detection is the use of cameras or image acquisition equipment to seal rubber ring image acquisition. Ensure clear, high-resolution images are taken in well-lit conditions. The acquired image is preprocessed, including the steps of grayscale, filter, binarization, etc. The key features of the sealing rubber ring, such as edge, contour, shape, size and defect information, are extracted from the pre-processed images. Through image processing algorithm and pattern recognition technology, the surface defects of sealing rubber ring, such as cracks, deformation, foreign matter, wear, etc., are detected and quantitatively evaluated. According to the extracted characteristics and test results, the sealing rubber ring is classified to determine whether it meets the quality standard. Thresholds or rules can be set for automatic determination. Finally, the test result is output as a report or feedback signal, indicating the quality of the sealing rubber ring.

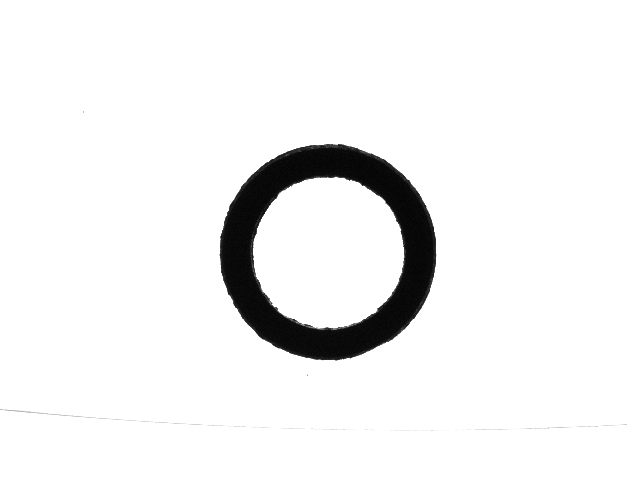

Detected object

【 Detection effect 】

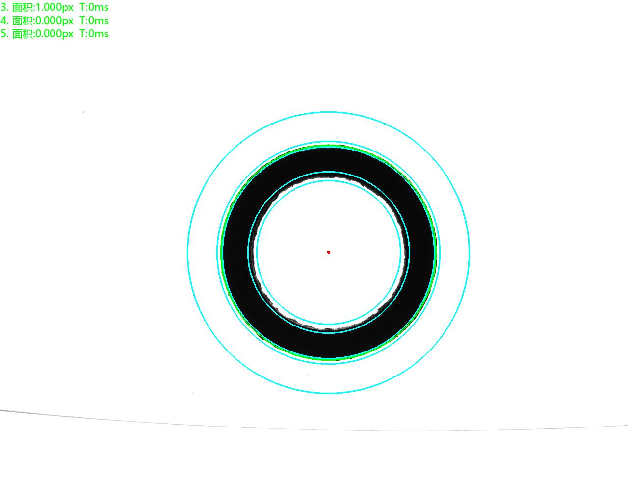

OK

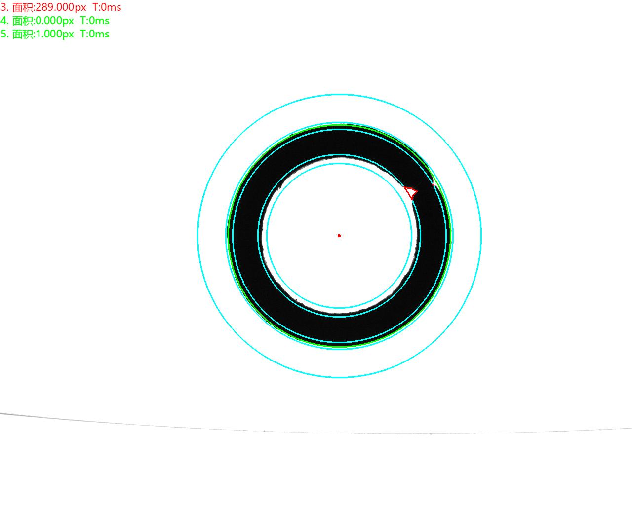

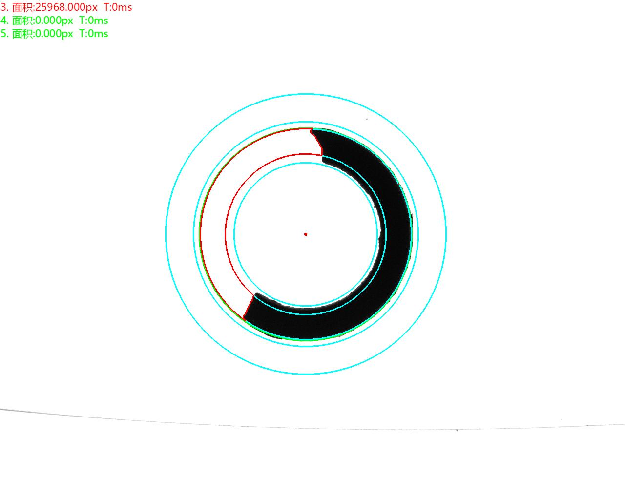

Top backlight detection of defective products analysis diagram: NG

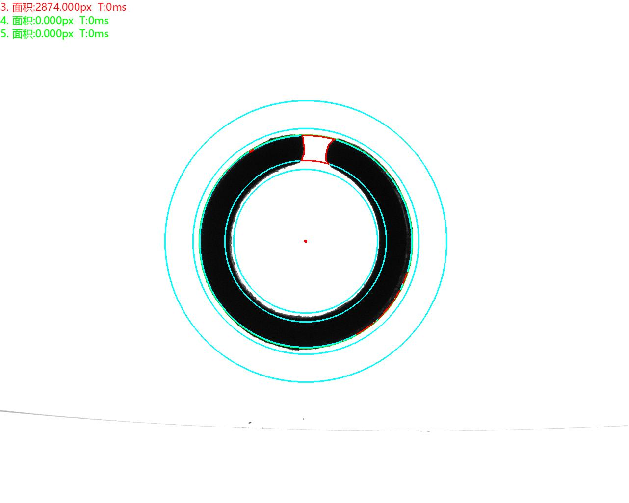

Top backlight detection of defective products analysis diagram: NG

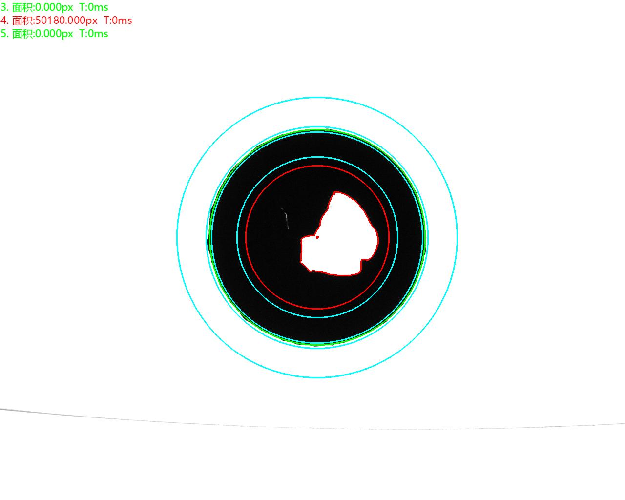

Top backlight detection of defective products analysis diagram: NG

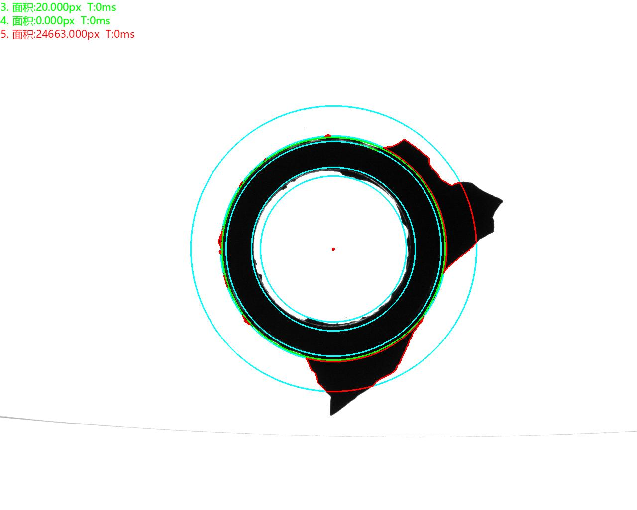

Top backlight detection of defective products analysis diagram: NG

Top backlight detection of defective products analysis diagram: NG

Top backlight detection defective product analysis diagram: NG Defective feature: external burr

-

Service hotline

13077808017