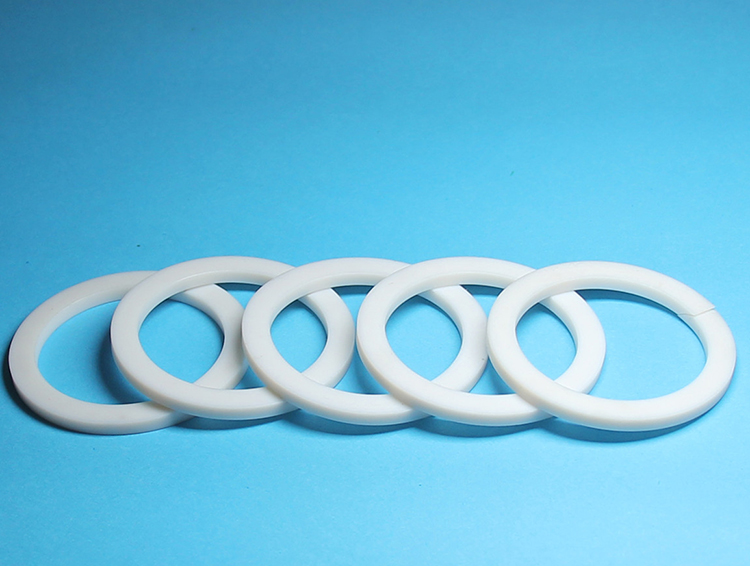

Application of CCD visual inspection technology in rubber products industry

The application of CCD visual inspection technology in the rubber products industry improves production efficiency, ensures product quality, reduces labor costs, and brings higher reliability and automation level to the production process. CCD visual inspection technology is widely used in rubber products industry

Quality control

CCD vision system is used to detect cracks, bubbles, depressions and other defects on the surface of rubber products. Test the size, shape and position of rubber products to ensure that products meet specifications.

Automated production

According to the detection results of the CCD vision system, the qualified and unqualified products are automatically classified. Accurately identify the position and direction of rubber products to achieve automatic processing and assembly.

Defect detection

Detect whether there is foreign matter in rubber products to ensure product quality. CCD system is used to detect the color consistency of rubber products to ensure the appearance quality of products.

Traceability and data analysis

Record the data detected by CCD vision system, traceability of production process and quality analysis. Real-time monitoring of the production process of rubber products, timely detection of problems and adjustments.

-

Service hotline

13077808017