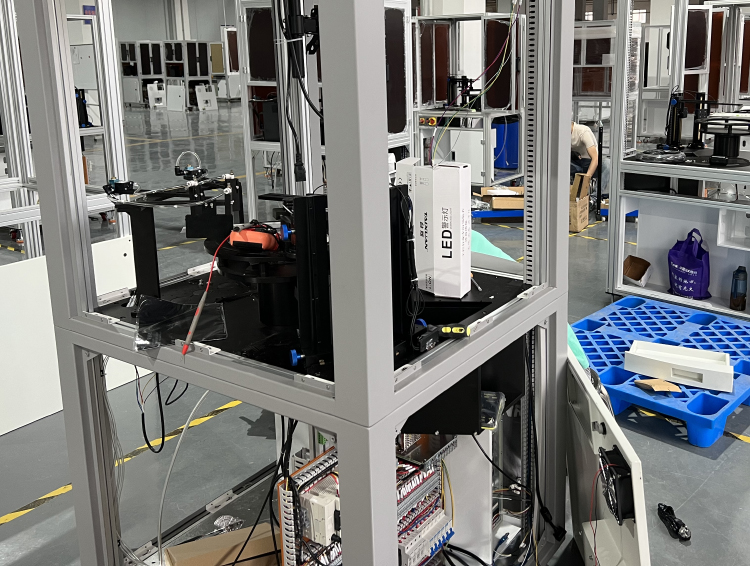

Visual inspection equipment error analysis

When selecting visual inspection equipment, it is necessary to fully understand its own needs, technical characteristics, and environmental requirements when selecting visual inspection equipment, and fully communicate and consult with professional suppliers or technicians to ensure that the appropriate equipment is selected to achieve the expected detection effect and production efficiency improvement.

Not understanding their specific application needs, including the required resolution, detection accuracy, detection speed, etc., will lead to the selection of unsuitable visual inspection equipment.

Excessive pursuit of low cost may lead to neglect of the performance and stability of the equipment, which may ultimately lead to higher maintenance costs and production losses.

If the lighting conditions, temperature, humidity and other factors of the actual working environment are not considered, the selected equipment may not work properly in a specific environment.

Not fully understanding the limitations and scope of application of visual inspection technology may lead to excessive expectations and fail to achieve the desired effect.

Not taking into account the expansion and upgrading of future production needs may lead to equipment that cannot meet long-term development needs.

If the device is too complex, the operation and maintenance costs may be too high. Therefore, select the appropriate device according to the actual requirements.

If the technical support and after-sales service of the device supplier are not considered, the stability and user experience of the device may be affected.

-

Service hotline

13077808017