Cloud disk high-speed detection machine capacitance detection scheme

Capacitance is a basic electrical component used to store charge and energy in the circuit. Capacitors are usually separated by an insulating medium (called dielectric) between two conductors to form an electric field. When the voltage is applied to the capacitor, the positive charge will accumulate on one plate, and the negative charge will accumulate on the other plate to form an electric field.

The capacitance value of the capacitor is in Farad, indicating the amount of charge the capacitor can store. The larger the capacitance value, the more charge the capacitor stores. The maximum voltage that the capacitor can withstand may cause damage to the capacitor. Polar capacitors have positive and negative polarity and need to be properly connected to avoid damage. Non-polar capacitors can be used in any direction in the circuit. The response of capacitors to signal frequency is frequency-related, and capacitors may show different characteristics under high-frequency signals. The loss angle of the capacitor is tangent to indicate the loss of energy. The smaller the forward shear of the loss angle, the better the performance of the capacitor.

Capacitors play an important role in electronic circuits, which are used for smoothing power supply, filtering, coupling signals, storing energy, etc. Common types of capacitors include electrolytic capacitors, ceramic capacitors, plastic capacitors, metallized polyester film capacitors, etc.

During the production process of the capacitor, defects such as shawl, tin point, scratches, dirt, material shortage, width size, character defects, etc. Siptek recommends the use of cloud disk high-speed vision detector.

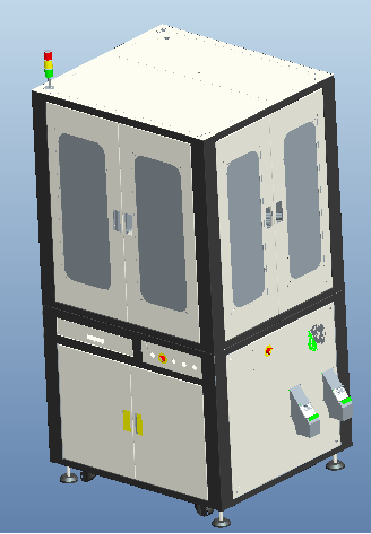

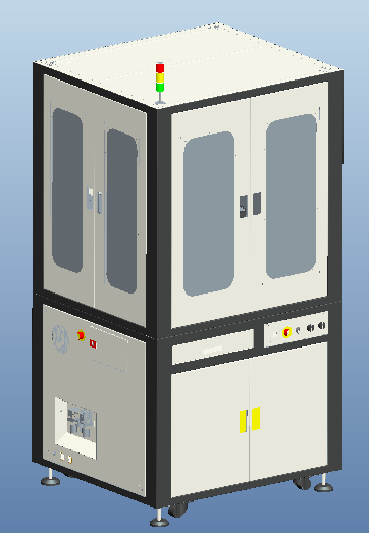

Cloud disk high-speed vision detector usually refers to a device or system that combines cloud computing, high-speed vision technology and automatic detection technology. Used on automated production lines to detect the quality, shape, size or other characteristics of a product or object, and to quickly make judgments or take corresponding measures. Using high-speed camera equipment and image processing algorithms, it can quickly capture and process a large amount of image information.

Through cloud computing technology, more efficient data storage, processing and analysis can be achieved, and real-time monitoring and feedback are supported. It can automatically identify and detect specific features of products or objects, such as defects, size deviations, etc., to achieve automated quality control. With fast response and processing capabilities, it is suitable for real-time detection needs on high-speed production lines.

Detection effect

Scratch

Tin point

Lack of material

Bad characters

Scratches

-

Service hotline

13077808017