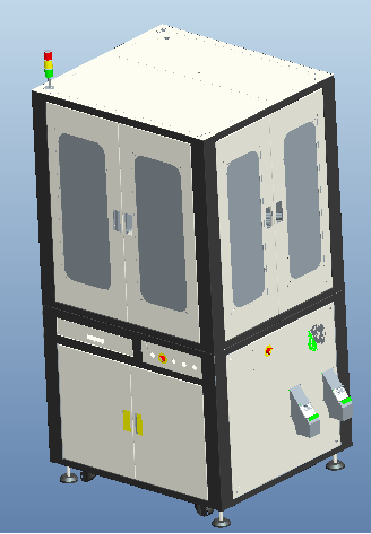

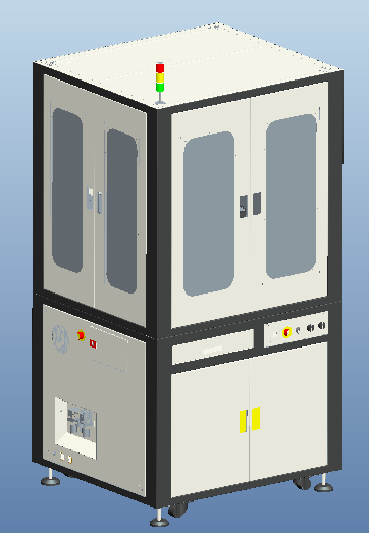

Cloud disk high-speed visual detector magnetoelectric detection scheme

Magnetoelectric effect refers to the electromagnetic coupling effect of a material under the action of an external magnetic field or electric field. Specifically, magnetoelectric effects usually include magnetostrictive effect, piezoelectromagnetic effect and magnetoelectric coupling effect.

When the material is in a magnetic field, a magnetostrictive effect will occur, that is, the size of the material will change slightly due to the existence of the magnetic field. Piezoelectric electromagnetic effect refers to the uneven distribution of charge when the material is subjected to mechanical stress (pressure), resulting in the magneticity of the material. Magnetoelectric coupling effect means that the material exhibits both magnetic and electrical properties, and the electrical or magnetic properties of the material can be controlled by adding a magnetic field or electric field.

In the process of magnetoelectric production, defects such as bumps (sand), missing corners, scratches, dimensions, side pits, etc. Siptek recommends the use of cloud disk high-speed vision detector.

High-speed visual inspection machine is a device that uses high-performance camera equipment and image processing technology to quickly and accurately carry out visual inspection and analysis. This machine is usually used on automated production lines and can detect the appearance, size, defects, marks, etc. of products to ensure product quality and production efficiency. The high-speed visual detector combines advanced visual algorithms and fast processing capabilities to capture, process and analyze a large amount of image data in an instant. This technology is widely used in electronic manufacturing, food packaging, pharmaceutical industry and other fields, which can help enterprises improve production quality and efficiency.

Detection effect

Lack of materials at the bottom

Lack of material at the top

Convex point

360° outer ring scratch

-

Service hotline

13077808017