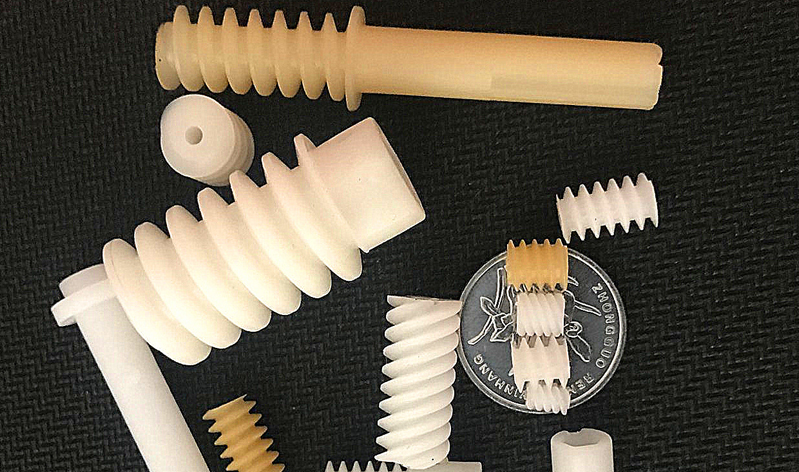

[Application Case] Plastic gear appearance visual inspection

Plastic visual inspection equipment is specially used for visual inspection and quality control in the production of plastic products.

Equipment characteristics

Wide applicability: It can be applied to the quality inspection of various plastic products, including injection parts, blow molded parts, extruded parts, etc.

High-precision detection: with high-resolution image acquisition equipment and precision algorithms, it can realize high-precision detection of defects, dimensions and appearance of plastic products.

Automated production: It can be integrated with the production line to realize the automatic detection and classification of plastic products and improve production efficiency.

Rapid detection: With high-speed processing capacity, it can quickly carry out the visual detection of large quantities of plastic products.

Real-time feedback: Support real-time feedback of test results to help production personnel adjust the production process in time.

Application

Plastic products manufacturing: used for injection molding parts, blow molding parts, extrusion parts and other plastic products quality inspection and appearance inspection.

Packaging industry: Used in plastic packaging products size detection, printing quality detection.

Medical equipment: Used for quality inspection and assembly inspection of medical plastic products.

Electronic industry: Used in electronic plastic parts welding quality testing, assembly testing, etc.

Item detection

Check the appearance of the product, whether there are cracks.

Equipment inspection

No less than 60 pieces per minute (depending on product feed speed). Detection accuracy: up to ±0.01mm, detection accuracy: 99.9%

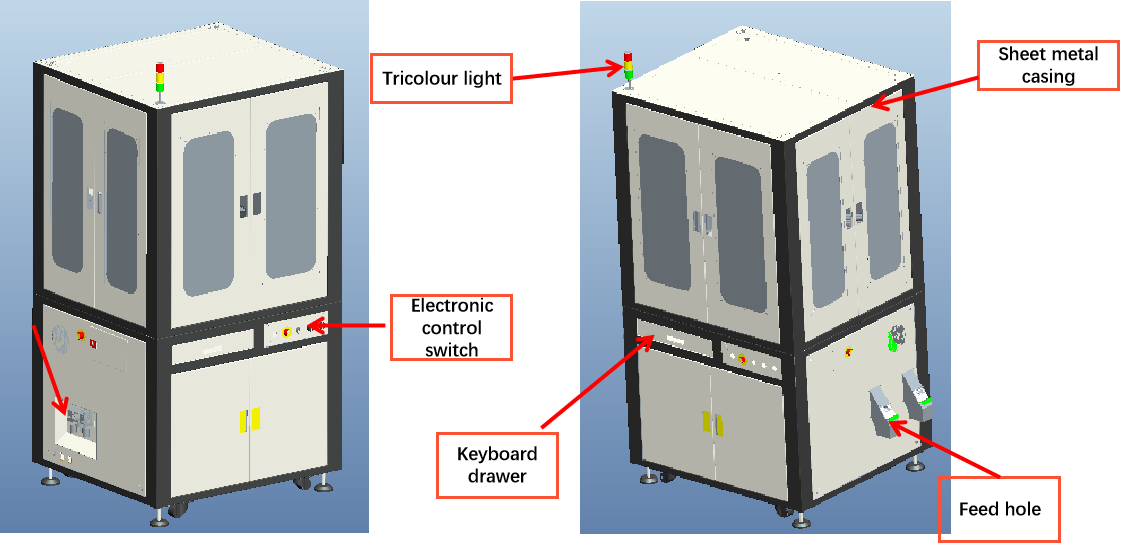

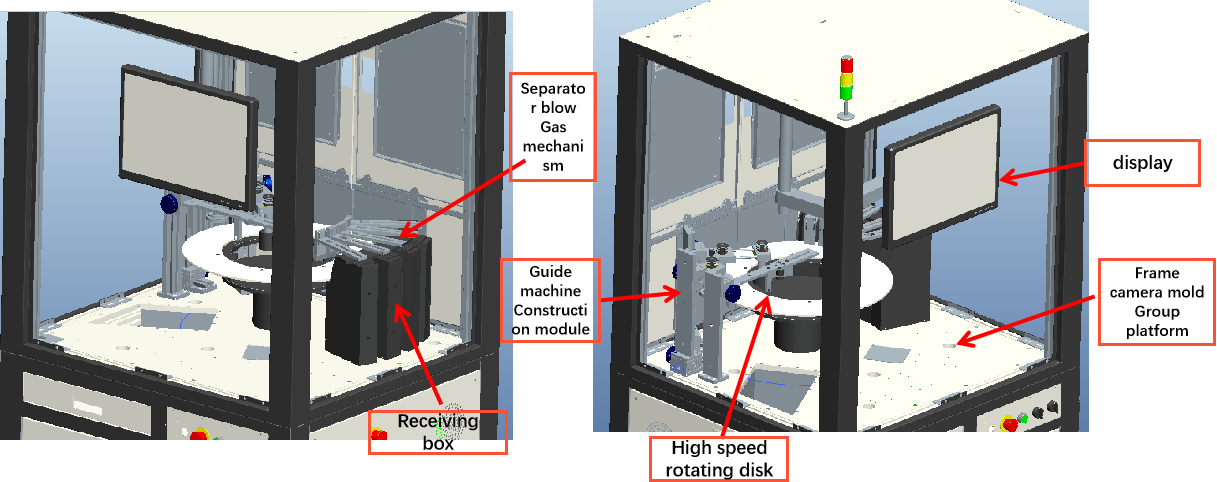

Equipment composition

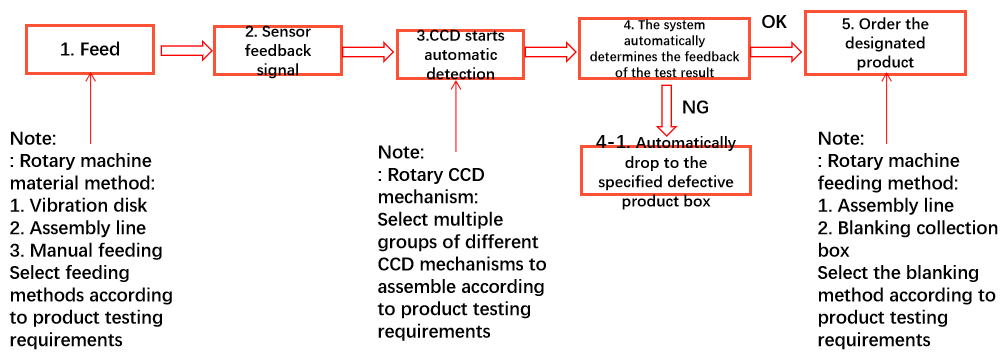

Equipment inspection process

【 Detection effect 】

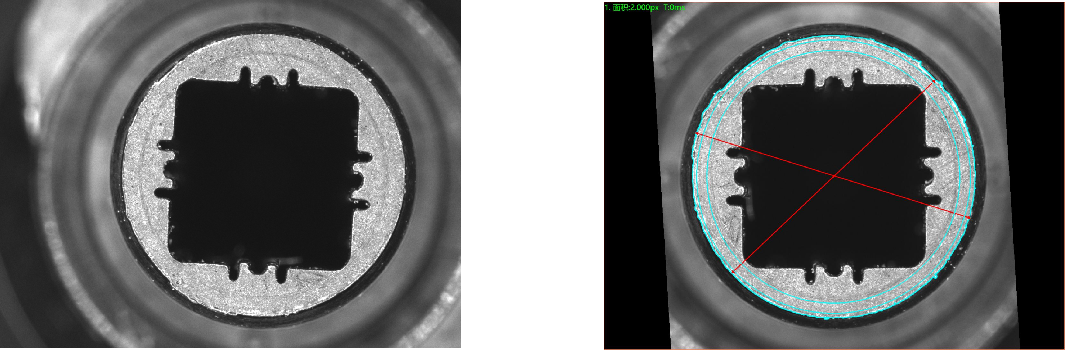

Top positive light detection good product map: OK

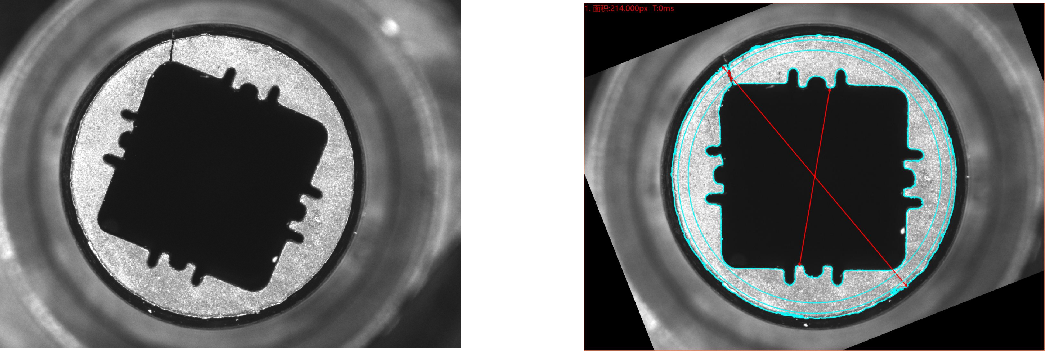

Top positive light detection of defective products: NG

Bad feature: Crack (severe)

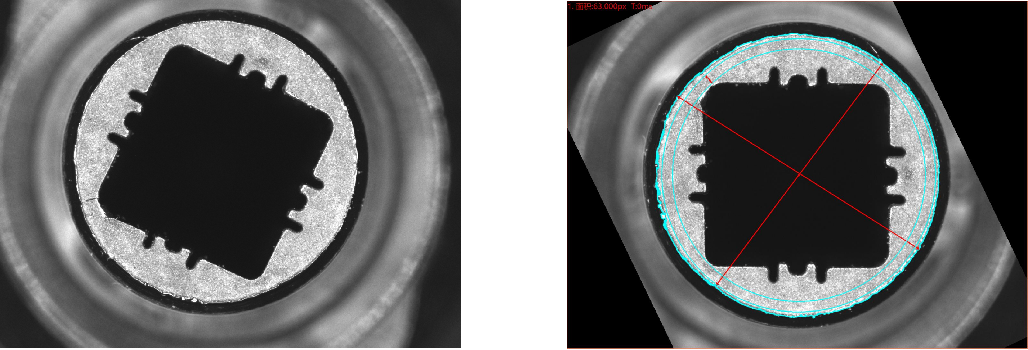

Camera 1, the top positive light detection of defective products: NG Bad features: cracks (slight)

-

Service hotline

13077808017